Supplier Management

Supply Chain Management

By evaluating each supplier’s supply quality, delivery date, and cooperation, the company avoids sourcing item of poor or insufficient quality which could affect product quality or production progress. We are also dedicated to strengthening information exchange with suppliers to reduce risk and increase sustainability, developing our core supply chain, and establishing long-term partnerships with suppliers.

1. Contractor Management

Chemical procurement and construction projects must notify the environmental safety unit, and remind the supplier of environmental safety and health related compliance matters in the purchase order to implement the company's obligations and make the procurement operation smooth.

In addition, when the contractor enters the factory for construction, the construction quality relies on the supervision and management of the on-site personnel of the factory, and the environmental safety, occupational safety, human rights and labor practices rely on the engineering and environmental safety units to monitor, and regularly report to the management to understand the situation.

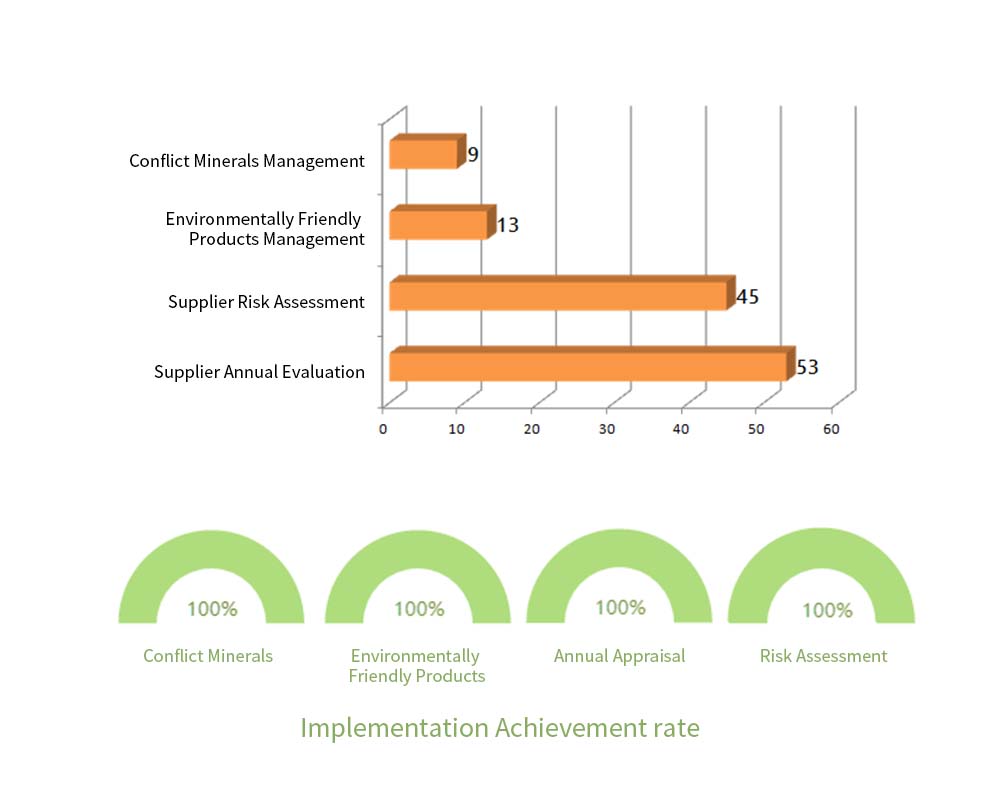

2. Evaluation Management

Establish long-term strategic partnerships with major raw material suppliers, and establish safety stocks based on the material preparation schedule to ensure a smooth supply chain. Every year, suppliers are evaluated based on quality, delivery, environmental protection, industrial safety, packaging, quality certification (preferably select manufacturers that have passed ISO9001, ISO14001, ISO45001, and CNS certification) and services. All suppliers are required to sign procurement and other related contracts to prevent any unfair or discriminatory behavior in procurement activities. Suppliers are required to sign the "Professional Ethics Compliance Statement" and "Conflict Minerals Non-use Statement" to ensure their labor and health business behaviors related to safety, environment, business ethics and management systems meet the requirements of the Responsible Business Alliance (RBA).

In addition to ensuring that the suppliers adopted by the company comply with the company’s sustainable business philosophy of environmental friendliness through annual supplier evaluation, the company and suppliers hold meetings to open a dialogue mechanism between the two parties. This is done in order to maintain long-term cooperation and exchanges, and to ensure a stable supply of main raw materials.

In addition, when the contractor enters the factory for construction, the construction quality relies on the supervision and management of the on-site personnel of the factory, and the environmental safety, occupational safety, human rights and labor practices rely on the quality of the engineering and environmental safety units to monitor the quality, and regularly report to the management to understand the situation.

3. Risk Management

Establish a material preparation mechanism for suppliers to avoid major supply chain disruptions. When a major disruption occurs, the operation of the raw material supply chain should be restored as soon as possible. Suppliers are required to carry out operational status, material source dispersion and supplier production line status returns, and proactively provide assistance when necessary to avoid purchasing materials from a single supplier. Therefore, procurement will develop high-quality suppliers at any time and maintain good relationships with existing suppliers to ensure that the supplier’s quality, cost, delivery, service, and management can meet the requirements of the factory. Internal demand can also reduce procurement risks. We implement risk assessments on suppliers every year, make assumptions about potential risks for suppliers’ risk issues, and confirm the risk levels of suppliers to implement risk treatment and countermeasures.

4. Management of Hazardous Substances

In order to make the products meet the customer's manufacturing process and related chemical requirements, including the EU Directive on the Prohibition of Hazardous Substances in Waste Electrical and Electronic Equipment (RoHS), we look forward to working with suppliers, starting with the purchase of product raw materials, and requesting suppliers to provide relevant information for review (Test report)We continue to work with suppliers on important issues such as society and the environment, and strive to achieve our goals of corporate social responsibility and environmental protection.

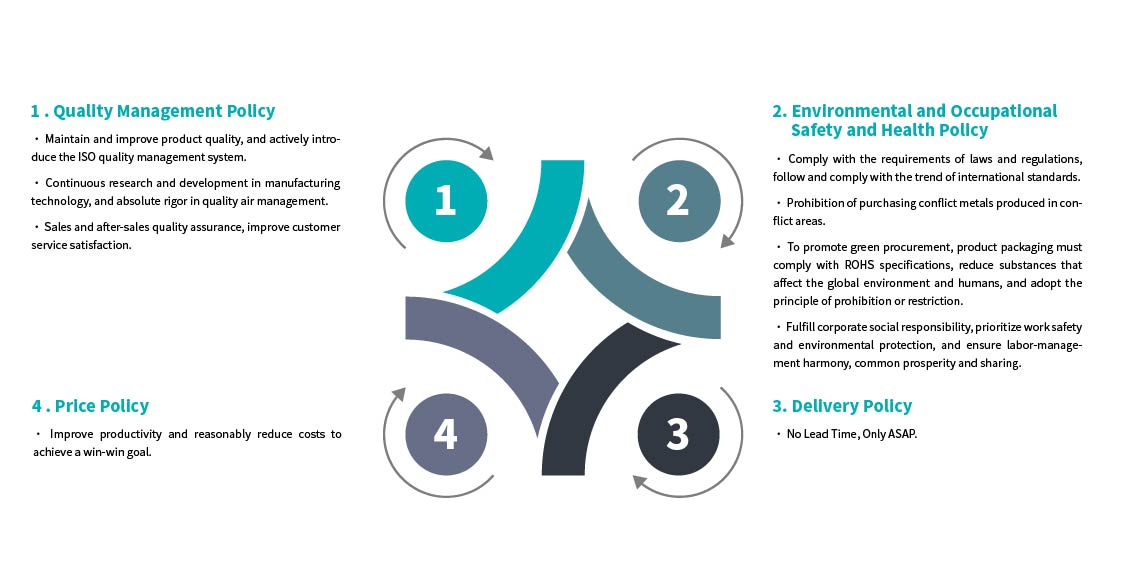

Four Policies for Quality Trust

Safety control-Strengthen Materials and Plant Operations

1. Origin: The Pursuit of Sustainability

Long-term strategy has been to create a safe environment for our personnel and reduce exposure to substances which could be harmful to employees.

2. Spirit: Thorough Inspection

Whether it is the entry of foreign personnel into the factory, the introduction of raw materials, or any situation admitting materials or personnel into the production site, a number of management items must be strictly checked to ensure that the operation process from beginning to the end of the entry into the factory meets the safety control standards.

3. Execution: All-Round

We expect that whether it is a colleague or contractor of CHPT, as long as they work in CHPT’s factory, they should be safe and secure, and the products produced from CHPT have high quality and reliability.

A. Personnel Control Standards

In order to avoid unnecessary disasters or environmental pollution for all suppliers’ employees in the CHPT factory, both foreign visitors and construction personnel must comply with safety control standards. Visitors must go through the application process prior to entering the factory. We shall check the qualifications of personnel, provide instructions on hazard identification and prevention before operation, and require safety protection during operation.

B. Product Control Standard

We hope that each raw material has a traceability record in its supply chain in a series of supply processes from source, manufacturing process, packaging, and delivery.

- Copyright © Chunghwa Precision Test Tech.Co., Ltd . All rights reserved.

- 中華精測科技股份有限公司 著作權所有